TIDMSHG

RNS Number : 8397N

Shanta Gold Limited

26 May 2020

26 May 2020

Shanta Gold Limited

("Shanta Gold", "Shanta" or the "Company")

Singida JORC Reserve Estimate and Resource Update

Shanta Gold (AIM: SHG), the East Africa-focused gold producer,

announces a JORC compliant Reserve and an updated and independently

verified JORC compliant Mineral Resource Estimate ("MRE" or

"Resource") on the Singida Gold Mining Project ("Singida" or "the

Project") in Central Tanzania.

Highlights

-- JORC 2012 compliant gold reserve of 243koz at 3.00g/t;

-- Over 90% of contained gold within the reserve is between

0-120 metres from surface, highlighting the potential for reserve

expansion at depth;

-- Updated life of mine plan to be released shortly;

-- Updated JORC compliant Mineral Resource at Singida totaling

11.8Mt, grading 2.38g/t and containing 904koz of gold, using a

cut-off grade of 1.0g/t, including;

o 17% increase in Measured and Indicated ("M&I") Mineral

Resource, totaling 5.7Mt, grading 2.66g/t and containing

484koz;

-- MRE has been independently estimated and verified by a third-party Competent Person; and,

-- Financing discussions for the development of Singida are

advanced and an announcement will follow, as appropriate.

Singida JORC Reserve

A JORC Reserve for the Singida Project has been declared,

amounting to 243,000 oz at 3.00 g/t. This Reserve represents a 50%

conversion of the Project's independently verified Measured and

Indicated Resource. An updated mine plan for the Project will

incorporate this Reserve and is expected to be released

shortly.

Singida JORC compliant MRE

The Project's MRE has been re-estimated and independently

verified by a third party Competent Person. This has resulted in a

total MRE of 904,000 oz at 2.38 g/t, including a 17% increase in

M&I Resources to 484,000 oz at 2.66g/t . This externally

verified MRE supports Shanta's previously announced internal

estimate and has formed the foundation of a JORC Reserve for the

Project.

Eric Zurrin, Chief Executive Officer, commented:

"The Singida reserve allows the Company to move forwards towards

construction and first production at Singida, confident in the fact

that we have a number of high-grade open pits. Importantly, it is

expected that this foundation will allow Singida to generate

significant cashflow to, amongst other things, pay for regional

exploration which will, over time, illuminate the Project's full

potential.

The Singida reserve sits within a substantial resource and is

located on a 4.9 km strike in a highly prospective greenstone belt.

The reserve represents just 26% of the existing total contained

resources and is nearly all within only 120 meters from surface,

highlighting the potential for reserve expansion. The Project is

fully permitted, and financing discussions are well advanced with

an announcement expected soon."

Enquiries:

Shanta Gold Limited

+ 255 (0) 22 292

Eric Zurrin (CEO) 5148

Luke Leslie (CFO)

Nominated Adviser and Broker

Numis Securities Limited

+ 44 (0) 20 7260

Paul Gillam / Alamgir Ahmed 1000

Financial Public Relations

Tavistock

Charles Vivian / Barnaby Hayward / Gareth + 44 (0) 20 7920

Tredway 3150

About Shanta Gold

Shanta Gold is an East Africa-focused gold producer. It

currently has defined ore resources on the New Luika and Singida

projects in Tanzania and holds exploration licenses covering

approximately 1,500km(2) in the country. In February 2020, Shanta

Gold entered into an agreement to acquire the West Kenya Project in

Kenya from subsidiaries of Barrick Gold Corporation. Shanta's

flagship New Luika Gold Mine commenced production in 2012 and

produced 84,506 ounces in 2019. The Company has been admitted to

trading on London's AIM and has approximately 794 m shares in

issue. For further information please visit:

www.shantagold.com.

This announcement contains inside information for the purposes

of Article 7 of Regulation 596/2014.

Competent Person

The Mineral Resource Estimate detailed which within this

announcement was completed by independent consultants - Pivot

Mining Consultants from South Africa. The technical information

contained within this announcement in respect of the updated

Mineral Resource Estimate has been reviewed and approved by Mr. Ken

Lomberg B.Sc. (Honours) Geology; B.Com (Economics and Statistics);

Meng (Mining Engineering), Pri.Sci.Nat. Mr. Lomberg is a consultant

to Shanta and a member of South African Council for Natural

Scientific Professionals (SACNASP) (Membership Number 400038/01).

He has sufficient experience that is relevant to the style of

mineralization and type of deposit under consideration and to the

activity being undertaken to qualify as a Competent Person as

defined in the 2012 Edition of the 'Australasian Code for Reporting

of Exploration Results, Mineral Resources and Ore Reserves' and for

the purposes of the AIM Guidance Note on Mining and Oil & Gas

Companies dated June 2009.

The technical information contained within this announcement in

respect of the updated Reserve estimate has been reviewed by Mr.

Jackson Kikota (the Company's Senior Mining Engineer), who is a

Member of The Australasian Institute of Mining and Metallurgy

(Aus.I.M.M). Mr. Kikota has sufficient experience that is relevant

to the style of mineralisation and type of deposit under

consideration and to the activity being undertaken to qualify as a

Competent Person as defined in the 2012 Edition of the

'Australasian Code for Reporting of Exploration Results, Mineral

Resources and Ore Reserves' and for the purposes of the AIM

Guidance Note on Mining and Oil & Gas Companies dated June

2009.

Singida JORC Reserve

The Project's JORC 2012 Reserve at 26 May 2020 is 2.51 Mt,

grading 3.00 g/t and containing 243,000 oz of gold at a cut-off

grade of 1.0 g/t. This Reserve is being incorporated into an

updated mine plan for the Project and represents an estimated 50%

conversion of the Project's independently verified Measured and

Indicated Resource. Of the total Reserve estimate, 91% of the

contained gold is within 120 metres from surface.

Singida Gold Project Tanzania

JORC 2012 Reserve(1)

(26 May 2020)

JORC 2012 Classification

DEPOSIT COG PROBABLE RESERVES

Tonnes Au_g/t Ounces,

Au

CORNPATCH 0.79 134,353 1.88 8,112

CORNPATCH

WEST 0.78 294,362 3.46 32,713

GOLD TREE 0.74 1,365,738 3.37 147,863

GUSTAV 0.78 128,867 1.70 7,059

JEM 0.74 324,153 2.86 29,843

KAIZER CHIEF 0.78 142,294 1.65 7,543

VIVIAN 0.74 124,654 2.38 9,532

TOTAL 0.75 2,514,421 3.00 242,666

----- ---------- ------- --------

(1) All deposits to be mined by open-pit method.

Singida Mineral Resource Estimate

The Singida Mineral Resource is based on seven shear-zone

related gold deposits with a combined strike length of 4.9 km. All

of these deposits are situated within three mining licenses. The

deposits trend east-west to north-west-south-east.

Singida Gold Project Tanzania

Mineral Resource Estimate (MRE) comparison

(26 May 2020 vs 20 January 2020)

JORC 2012 Classification

26-May-20 20-Jan-20 Change

Tonnes Grade Gold Tonnes Grade Gold Tonnes Grade Gold

Mt g/t 000s Mt g/t 000s Mt % change 000s

oz oz oz

Measured 1.63 3.39 179 - - - 1.63 n/a 179

Indicated 4.02 2.36 306 4.88 2.63 412 (0.86) (10%) (106)

Subtotal

- M&I 5.65 2.66 484 4.88 2.63 412 0.77 1% 72

Inferred 6.15 2.12 418 7.84 2.01 507 (1.69) 5% (89)

Total 11.80 2.38 904 12.72 2.25 919 (0.92) 6% (15)

Mineral Resources

The Project's Mineral Resource is based on seven-shear zone

related gold deposits with a combined strike length of 4.9km.

Historical drilling has identified mineralisation extending down to

500m from the surface in the Gold Tree deposit.

The Measured and Indicated Resource at 26 May 2020 is an

estimated 5.65 Mt, grading 2.66 g/t and containing 484,000 oz of

gold at a cut-off grade of 1.0 g/t. The majority of these resources

are less than 120 metres from surface.

Estimated Inferred Resources total 6.15 Mt, grading 2.12 g/t and

containing 418,000 oz of gold at a cut-off grade of 1.0 g/t.

Singida Gold Project Tanzania

Mineral Resource Estimate (MRE)

(26 May 2020)

JORC 2012 Classification

MEASURED INDICATED INFERRED TOTAL RESOURCES

------------------------- ------------------------- -------------------------

TONNES GRADES OUNCES TONNES GRADES OUNCES TONNES GRADES OUNCES TONNES GRADES OUNCES

('000) g/t ('000 ('000) g/t ('000 ('000) g/t ('000 ('000) g/t ('000

oz) oz) oz) oz)

------- ------- ------- ------- ------- ------- ------- ------- ------- ------- ------- -------

CORNPATCH 117 2.00 8 336 1.98 22 517 2.36 39 970 2.18 69

CORNPATCH

WEST - - - 824 2.52 67 565 1.87 34 1,389 2.26 101

GOLD

TREE 1,139 3.66 135 1,294 2.39 100 3,274 2.02 213 5,707 2.43 447

GUSTAV - - - 148 1.49 7 783 1.85 47 932 1.79 54

JEM 376 2.99 36 542 2.67 46 532 2.92 50 1,451 2.84 133

KAIZER

CHIEF - - - 475 1.67 25 354 1.98 22 828 1.80 48

VIVIAN - - - 405 2.97 38 125 3.40 14 529 3.07 52

TOTAL 1,632 3.39 179 4,024 2.36 305 6,150 2.12 418 11,806 2.38 904

------- ------- ------- ------- ------- ------- ------- ------- ------- ------- ------- -------

Glossary

Glossary of Technical Terms

"Au" chemical symbol for gold

"cut off the lowest grade value that is included in a

grade" (COG) resource statement. It must comply with JORC

requirement 19: "reasonable prospects for eventual

economic extraction" the lowest grade, or quality,

of mineralised material that qualifies as economically

mineable and available in a given deposit. It

may be defined on the basis of economic evaluation,

or on physical or chemical attributes that define

an acceptable product specification

"g/t" grammes per tonne, equivalent to parts per million

"Inferred that part of a Mineral Resource for which tonnage,

Resource" grade and mineral content can be estimated with

a low level of confidence. It is inferred from

geological evidence and assumed but not verified

geological and/or grade continuity. It is based

on information gathered through appropriate

techniques from locations such as outcrops,

trenches, pits, workings and drill holes which

may be limited or of uncertain quality and reliability

"Indicated that part of a Mineral Resource for which tonnage,

Resource" densities, shape, physical characteristics,

grade and mineral content can be estimated with

a reasonable level of confidence. It is based

on exploration, sampling and testing information

gathered through appropriate techniques from

locations such as outcrops, trenches, pits,

workings and drill holes. The locations are

too widely or inappropriately spaced to confirm

geological and/or grade continuity but are spaced

closely enough for continuity to be assumed

"JORC" The Australasian Joint Ore Reserves Committee

Code for Reporting of Exploration Results, Mineral

Resources and Ore Reserves 2012 (the "JORC Code"

or "the Code"). The Code sets out minimum standards,

recommendations and guidelines for Public Reporting

in Australasia of Exploration Results, Mineral

Resources and Ore Reserves

"koz" thousand troy ounces of gold

"Measured that part of a Mineral Resource for which tonnage,

Resource" densities, shape, physical characteristics,

grade and mineral content can be estimated with

a high level of confidence. It is based on detailed

and reliable exploration, sampling and testing

information gathered through appropriate techniques

from locations such as outcrops, trenches, pits,

workings and drill holes. The locations are

spaced closely enough to confirm geological

and grade continuity

"Mineral a concentration or occurrence of material of

Resource" intrinsic economic interest in or on the Earth's

crust in such form, quality and quantity that

there are reasonable prospects for eventual

economic extraction. The location, quantity,

grade, geological characteristics and continuity

of a Mineral Resource are known, estimated or

interpreted from specific geological evidence

and knowledge. Mineral Resources are sub-divided,

in order of increasing geological confidence,

into Inferred, Indicated and Measured categories

when reporting under JORC

"Mt" million tonnes

"oz" troy ounce (= 31.103477 grammes)

"Reserve" the economically mineable part of a Measured

and/or Indicated Mineral Resource

"t" tonne (= 1 million grammes)

APPIX 1: SAMPLING TECHNIQUES AND DATA

Sampling

techniques * Nature and quality of sampling (eg cut channels, * Diamond drilling 1m samples

random chips, or specific specialised industry

standard measurement tools appropriate to the

minerals under investigation, such as down hole gamma * Reverse circulation (RC) drilling was used to obtain

sondes, or handheld XRF instruments, etc). These 1 m samples from which 3 kg of material was sent for

examples should not be taken as limiting the broad analysis

meaning of sampling.

* Drilling sampled on a maximum of 1 m downhole

* Include reference to measures taken to ensure sample

representivity and the appropriate calibration of any

measurement tools or systems used. * Samples were not composited

* Aspects of the determination of mineralisation that * Samples were submitted to the SGS Laboratory in

are Material to the Public Report. Mwanza for analysis

* In cases where 'industry standard' work has been done * At least 3kg sample pulverized and a 50g charge fire

this would be relatively simple (eg 'reverse assayed with AAS or aqua regia finish for gold

circulation drilling was used to obtain 1 m samples

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases more

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (eg

submarine nodules) may warrant disclosure of detailed

information.

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * Diamond core drilling; NQ core size

hammer, rotary air blast, auger, Bangka, sonic, etc)

and details (eg core diameter, triple or standard

tube, depth of diamond tails, face-sampling bit or * RC Drilling

other type, whether core is oriented and if so, by

what method, etc).

Drill

sample * Method of recording and assessing core and chip * Core sample recoveries routinely measured and

recovery sample recoveries and results assessed. recorded in spreadsheet database

* Measures taken to maximise sample recovery and ensure * Samples split half core perpendicular to strike of

representative nature of the samples. mineralized zones

* Whether a relationship exists between sample recovery * RC samples recovered from on-site cyclone

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse

material.

Logging

* Whether core and chip samples have been geologically * Logging of geology, alteration and geotechnical

and geotechnically logged to a level of detail to aspects recorded in drill logs for diamond core

support appropriate Mineral Resource estimation, drilling

mining studies and metallurgical studies.

* Logging is qualitative; All drill core is

* Whether logging is qualitative or quantitative in photographed

nature. Core (or costean, channel, etc) photography.

* Entire intervals that were drilled and/or trenched

* The total length and percentage of the relevant were logged

intersections logged.

Sub-sampling

techniques * If core, whether cut or sawn and whether quarter, * Half core taken; Sawn

and half or all core taken.

sample

preparation * RC samples riffled and sub-sample; Submitted for

* If non-core, whether riffled, tube sampled, rotary analysis

split, etc and whether sampled wet or dry.

* For trench samples, the entire sample for the

* For all sample types, the nature, quality and respective interval aggregated, not riffled or split

appropriateness of the sample preparation technique.

* Aggregated half core; Entire 3kg sample pulverized at

* Quality control procedures adopted for all laboratory prior to fire assay in order to minimize

sub-sampling stages to maximise representivity of bias

samples.

* Drilling and channels planned orthogonal to the

* Measures taken to ensure that the sampling is strike of structures/lithologies in order to maximize

representative of the in situ material collected, representivity

including for instance results for field

duplicate/second-half sampling.

* Field duplicates sampled at appropriate intervals

* Whether sample sizes are appropriate to the grain

size of the material being sampled.

Quality

of * The nature, quality and appropriateness of the * Fire assay is appropriate for the nature of gold

assay assaying and laboratory procedures used and whether mineralization being assayed

data the technique is considered partial or total.

and

laboratory * No geophysical tools used to generate exploration

tests * For geophysical tools, spectrometers, handheld XRF results

instruments, etc, the parameters used in determining

the analysis including instrument make and model,

reading times, calibrations factors applied and their * Registered reference material inserted at the

derivation, etc. interval of 20 samples

* Nature of quality control procedures adopted (eg * Levels of accuracy and precision (detection limit)

standards, blanks, duplicates, external laboratory for gold is 0.01 ppm which is suitable for the level

checks) and whether acceptable levels of accuracy (ie of assays reported

lack of bias) and precision have been established.

Verification

of * The verification of significant intersections by * No twinning of drillholes

sampling either independent or alternative company personnel.

and

assaying * Primary data was logged onto paper and later

* The use of twinned holes. transferred into database, verified by a Senior

Geologist and stored in electronic database that is

regularly backed up

* Documentation of primary data, data entry procedures,

data verification, data storage (physical and

electronic) protocols. * Database is verified and compared with standard

assays stored using established company protocols

* Discuss any adjustment to assay data.

* No adjustments have been made to assay data

Location

of * Accuracy and quality of surveys used to locate drill * Drillholes and trenches were accurately surveyed

data holes (collar and down-hole surveys), trenches, mine using Trimble DGPS survey equipment

points workings and other locations used in Mineral Resource

estimation.

* Drillholes and trenches surveyed in UTM Coordinates

System Arc 1960

* Specification of the grid system used.

* Topographical surveys were done using Aerial Lidar

* Quality and adequacy of topographic control. Survey

Data

spacing * Data spacing for reporting of Exploration Results. * Drillhole spacing was generally at 50m along strike

and of the targets with a vertical spacing of

distribution approximately 40 to 50m

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and

grade continuity appropriate for the Mineral Resource

and Ore Reserve estimation procedure(s) and

classifications applied.

* Whether sample compositing has been applied.

Orientation

of * Whether the orientation of sampling achieves unbiased * Drilling and trenching planned perpendicular to the

data sampling of possible structures and the extent to interpreted strike of lithological units and

in which this is known, considering the deposit type. geological structures

relation

to

geological * If the relationship between the drilling orientation

structure and the orientation of key mineralised structures is

considered to have introduced a sampling bias, this

should be assessed and reported if material.

Sample

security * The measures taken to ensure sample security. * Samples secured by senior personnel on site and

transported directly by company vehicle to the

laboratories (Quality Labs in NLGM and SGS in Mwanza)

Audits

or * The results of any audits or reviews of sampling * Internal reviews are regularly completed but no

reviews techniques and data. external audits were carried out for the currently

reported results

============= ============================================================ ============================================================

APPIX 2: REPORTING OF EXPLORATION RESULTS

Mineral

tenement * Type, reference name/number, location and ownership * ML 456/2012 valid until 19 Jan 2022

and including agreements or material issues with third

land parties such as joint ventures, partnerships,

tenure overriding royalties, native title interests, * ML 455/2012 valid until 19 Jan 2022

status historical sites, wilderness or national park and

environmental settings.

* ML 457/2012 valid until 19 Jan 2022

* The security of the tenure held at the time of

reporting along with any known impediments to

obtaining a licence to operate in the area.

Exploration

done * Acknowledgment and appraisal of exploration by other * Historical colonial exploration and mining works

by parties.

other

parties

Geology

* Deposit type, geological setting and style of * Underlain by a complex association of high grade

mineralisation. metamorphic- and intrusive lithologies, commonly

intruded by dykes of variable composition. Modally,

granodioritic and granitic lithologies are most

commonly encountered.

* These granodiorites and granites have been

interpreted as late-orogenic intrusive phases

associated with gold mineralisation in the area.

Subordinate diorite, porphyroblastic hornblende

gabbro, quartzo-feldspathic felsite and migmatite are

also regularly observed.

* Dyke intrusives include dolerite, pegmatite and

common aplite and alaskite, seemingly randomly

crosscutting major lithologies, and therefore

regarded as younger than the country rock.

Drill

hole * A summary of all information material to the * Relevant tables included summarizing drill holes and

Information understanding of the exploration results including a trenches locations, RL, azimuth, length/depth, and

tabulation of the following information for all significant intersection intervals

Material drill holes:

o

easting

and

northing

of

the

drill

hole

collar

o

elevation

or

RL

(Reduced

Level

-

elevation

above

sea

level

in

metres)

of

the

drill

hole

collar

o

dip

and

azimuth

of

the

hole

o

down

hole

length

and

interception

depth

o

hole

length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

Data

aggregation * In reporting Exploration Results, weighting averaging * Exploration results from drilling and trench sampling

methods techniques, maximum and/or minimum grade truncations have been weighted by interval

(eg cutting of high grades) and cut-off grades are

usually Material and should be stated.

* High-grade caps have been applied

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade * Lower cut-off grade of 0.5 g/t Au has generally been

results, the procedure used for such aggregation applied to significant intersections

should be stated and some typical examples of such

aggregations should be shown in detail.

* Aggregate drilling and trenching intervals do not

incorporate longer lengths of low-grade results

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

* No metal equivalent reported

Relationship

between * These relationships are particularly important in the * Drill holes and trenches have been drilled/excavated

mineralisation reporting of Exploration Results. as perpendicular as possible to the general strike of

widths the mineralized zones and structures so that the

and intersected lengths are close to true widths

intercept * If the geometry of the mineralisation with respect to

lengths the drill hole angle is known, its nature should be

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (eg 'down hole length, true width not known').

Diagrams

* Appropriate maps and sections (with scales) and * Maps and sections are being generated

tabulations of intercepts should be included for any

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

Balanced

reporting * Where comprehensive reporting of all Exploration * All significant drilling and trench results have been

Results is not practicable, representative reporting reported

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

Other

substantive * Other exploration data, if meaningful and material, * Metallurgical studies of the ore from potential five

exploration should be reported including (but not limited to): pits were conducted and completed by SGS in South

data geological observations; geophysical survey results; Africa in 2009. The ore minerology variability is

geochemical survey results; bulk samples - size and insignificant but relatively coarse gold grain was

method of treatment; metallurgical test results; bulk observed

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances. * The relatively coarse nature of much of the gold

provides reason for an upfront gravity circuit to

recover coarse gold prior to cyanidation. An overall

gold recovery of 90% can be achieved through gold

dissolution by direct cyanidation and the gravity

concentrator.

Further

work * The nature and scale of planned further work (eg * Drilling to be continued to test along strike and the

tests for lateral extensions or depth extensions or down-dip continuity of the delineated mineralization

large-scale step-out drilling).

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

=============== =============================================================== ============================================================

APPIX 3: ESTIMATION AND REPORTING OF MINERAL RESOURCES

Database

integrity * Measures taken to ensure that data has not been * The data capturing Access database is linked to a

corrupted by, for example, transcription or keying superseding Access database on the geological server

errors, between its initial collection and its use

for Mineral Resource estimation purposes.

* Queries allow specially selected information from the

captured data and create core data sheets which

* Data validation procedures used. include Collar, Survey, Lithology and Assay logs.

These logs are essentially used to display in the

mining software by an OBDC link

* An independent validation process is run for each log

sheet in Micromine by Shanta. Should there be any

queries, a report file is created and exported to

excel. The report will be mailed to the personnel

responsible for data capturing to correct on the

original data

* Once confirmation is given of the updates, all

databases are refreshed and the validation process in

Micromine and Surpac repeated with the use of form

sets

* Once all data validates, a number for the tear of

validation is indicated in the collar file of the

superseding database

Site

visits * Comment on any site visits undertaken by the * Dr Corné Koegelenberg, assisted by Mr Jonathan

Competent Person and the outcome of those visits. Gloyn-Jones, visited the property from the 14 - 20th

of February 2020 to conduct a drill core

investigation of macrostructural and gold

* If no site visits have been undertaken indicate why mineralization features. Mr Ken Lomberg joined the

this is the case. site visit from the 19 - 20th of February 2020

Geological

interpretation * Confidence in (or conversely, the uncertainty of ) * Diamond drilling was done perpendicular to the strike

the geological interpretation of the mineral deposit. of the ore body at a dip designed to give a true

intersection width of the mineralized body at a

spacing less than 42m

* Nature of the data used and of any assumptions made.

* The downhole survey was done at every 15m

* The effect, if any, of alternative interpretations on

Mineral Resource estimation.

* Core meter marking, geological logging, structural

interpretation, core sampling, Data validation and

* The use of geology in guiding and controlling Mineral QAQC analysis was done by competent and experienced

Resource estimation. geologists

* The factors affecting continuity both of grade and * Only samples submitted to the accredited laboratory

geology. (SGS Mwanza) are used in the estimate

* The limits of the structural features hosting the

mineralized zone was interpreted by overlaying the

assays against geological logging section by section

using section strings

Dimensions

* The extent and variability of the Mineral Resource * Drill hole spacing is generally between 25 to 42m

expressed as length (along strike or otherwise), plan along with a vertical spacing of approximately 20 to

width, and depth below surface to the upper and lower 38m in the upper to mid-level portions of the

limits of the Mineral Resource. mineralized zones. This drilling spacing combined

with the surface exposures and trench sampling, along

with the geophysical data, permits the assumption

that both the mineralized structures are continuous

and persistent, and the mineralization within the

structures has the continuity necessary to consider

these deposits as Mineral Resources

Estimation

and * The nature and appropriateness of the estimation * Compositing data into regular composite intervals was

modelling technique(s) applied and key assumptions, including performed to moderate the presence of extreme short

techniques treatment of extreme grade values, domaining, sample interval grade values in the data, by

interpolation parameters and maximum distance of combining them with adjacent data to form the

extrapolation from data points. If a computer composite

assisted estimation method was chosen include a

description of computer software and parameters used.

* A combination of several methods was used to decide

what constitutes an appropriate capping value. The

* The availability of check estimates, previous spatial position of outlier values, as well as

estimates and/or mine production records and whether coefficient of variation plots, lognormal probability

the Mineral Resource estimate takes appropriate plots and decile analysis, were used in the

account of such data. determination of capping values

* The assumptions made regarding recovery of * Scatter plots of the gold grade composites versus

by-products. location were generated, to assess any potential

non-stationarity in the data

* Estimation of deleterious elements or other non-grade

variables of economic significance (eg sulphur for * Block models were created to represent the

acid mine drainage characterisation). mineralized body contained within the wireframe

solids for each target. Cell sizes were chosen based

on the average drillhole spacing

* In the case of block model interpolation, the block

size in relation to the average sample spacing and

the search employed. * Geostatistics was performed using Datamine Studio RM

to determine the estimation parameters

* Any assumptions behind modelling of selective mining

units. * The mineralized targets were modelled for gold grade

using Ordinary Kriging, with the shell of the

wireframe solid as a hard boundary. Only data within

* Any assumptions about correlation between variables. the solid was used in the estimate

* Description of how the geological interpretation was * The Estimation process used Datamine Studio RM

used to control the resource estimates. software for all block grade estimates

* Discussion of basis for using or not using grade

cutting or capping.

* The process of validation, the checking process used,

the comparison of model data to drill hole data, and

use of reconciliation data if available.

Moisture

* Whether the tonnages are estimated on a dry basis or * Tonnages are reported on a dry basis

with natural moisture, and the method of

determination of the moisture content.

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * A simple financial assessment was undertaken to

parameters applied. ascertain whether they fulfil the criteria of

"reasonable prospects for eventual economic

extraction" using current operating costs

Mining

factors * Assumptions made regarding possible mining methods, * The mineral resource was deemed amenable to

or minimum mining dimensions and internal (or, if extraction by open pit mining method and were

assumptions applicable, external) mining dilution. It is always declared at a cut-off of 1.0g/t

necessary as part of the process of determining

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the

assumptions made regarding mining methods and

parameters when estimating Mineral Resources may not

always be rigorous. Where this is the case, this

should be reported with an explanation of the basis

of the mining assumptions made.

Metallurgical

factors * The basis for assumptions or predictions regarding * Shanta commissioned the first of a series of gold

or metallurgical amenability. It is always necessary as deportment and metallurgical studies on mineralized

assumptions part of the process of determining reasonable material from potential pits in 2009. Reverse

prospects for eventual economic extraction to circulation drill chips from five mineralised targets

consider potential metallurgical methods, but the were submitted for gold deportment studies in order

assumptions regarding metallurgical treatment to understand the mode of gold occurrence, and to

processes and parameters made when reporting Mineral ascertain possible cost effective and practical

Resources may not always be rigorous. Where this is process routes.

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made.

* Further metallurgical studies commissioned on

mineralized material from the Gold Tree (Tree Top and

Tree Bottom) deposit in 2011 support initial gold

deportment findings. A report from Mintek summarized

that the ore contains coarse gold which should be

recovered prior to the leaching process with an

overall gold recovery 90% - Mintek External Report

No: 5887 of February 2011).

Environmental

factors * Assumptions made regarding possible waste and process * Shanta Mining Company Limited is fully permitted

or residue disposal options. It is always necessary as mining operation under Tanzanian law with the

assumptions part of the process of determining reasonable prerequisite Environmental Impact Assessments (EIA)

prospects for eventual economic extraction to issued in 2019.

consider the potential environmental impacts of the

mining and processing operation. While at this stage

the determination of potential environmental impacts,

particularly for a greenfields project, may not

always be well advanced, the status of early

consideration of these potential environmental

impacts should be reported. Where these aspects have

not been considered this should be reported with an

explanation of the environmental assumptions made.

Bulk

density * Whether assumed or determined. If assumed, the basis * Density determinations have been carried out on the

for the assumptions. If determined, the method used, diamond cores. The results ranged from 2.82 g/cm(3)

whether wet or dry, the frequency of the measurements to 3.15 g/cm(3)

,

the nature, size and representativeness of the

samples.

* The bulk density for bulk material must have been

measured by methods that adequately account for void

spaces (vugs, porosity, etc), moisture and

differences between rock and alteration zones within

the deposit.

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

Classification

* The basis for the classification of the Mineral * The resources have been classified as Measured,

Resources into varying confidence categories. Indicated and Inferred based primarily on sample

spacing as determined by drilling density and

proximity to informing data as well as the grade

* Whether appropriate account has been taken of all distribution of the supporting data. For the resource

relevant factors (ie relative confidence in classification, a solid shape was constructed around

tonnage/grade estimations, reliability of input data, the parts of the mineralised body where most

confidence in continuity of geology and metal values, estimates were informed by data not more than 30m

quality, quantity and distribution of the data). from the estimated block, are estimated within the

primary search volume, and where the estimates have

been interpolated rather than extrapolated. All

* Whether the result appropriately reflects the blocks located within these areas were classified as

Competent Person's view of the deposit. Measured and Indicated resources. All blocks located

outside of these areas, around the periphery of the

drilling were classified as Inferred resources

Audits

or * The results of any audits or reviews of Mineral * Only internal audit completed

reviews Resource estimates.

Discussion

of * Where appropriate a statement of the relative * Refer Estimation and modelling techniques comments

relative accuracy and confidence level in the Mineral Resource above

accuracy/ estimate using an approach or procedure deemed

confidence appropriate by the Competent Person. For example, the

application of statistical or geostatistical

procedures to quantify the relative accuracy of the

resource within stated confidence limits, or, if such

an approach is not deemed appropriate, a qualitative

discussion of the factors that could affect the

relative accuracy and confidence of the estimate.

* The statement should specify whether it relates to

global or local estimates, and, if local, state the

relevant tonnages, which should be relevant to

technical and economic evaluation. Documentation

should include assumptions made and the procedures

used.

* These statements of relative accuracy and confidence

of the estimate should be compared with production

data, where available.

=============== ============================================================ ============================================================

S

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

END

DRLEADSSADKEEAA

(END) Dow Jones Newswires

May 26, 2020 02:01 ET (06:01 GMT)

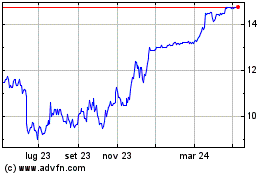

Grafico Azioni Shanta Gold (LSE:SHG)

Storico

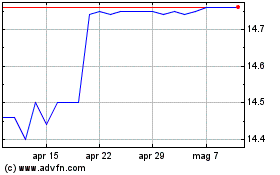

Da Mar 2024 a Apr 2024

Grafico Azioni Shanta Gold (LSE:SHG)

Storico

Da Apr 2023 a Apr 2024