Metallurgical Testing

07 Giugno 2010 - 9:01AM

UK Regulatory

TIDMBKY

RNS Number : 1515N

Berkeley Resources Limited

07 June 2010

7 June 2010

BERKELEY RESOURCES LIMITED

Salamanca Uranium Project

Metallurgical Test Work Update

Berkeley Resources Limited is pleased to announce the commencement of the

metallurgical test work and initial results from the Salamanca Uranium Project

in Spain. The first round of dynamic leach tests have produced encouraging

results with uranium extraction up to 93% generated in acid batch leach tests

for bulk samples from Palacios and Sageras. Acid leach is a proven technology

and was previously used in the Salamanca Operation (from 1994 to 2003) at the

Quercus Processing Plant.

The key results from the test work completed to date at the SGS Lakefield

Laboratory in Perth, Australia, are summarised below:

· Leach recoveries greater than 93% at Palacios and 87% at Sageras using an

acid based process;

· A relatively coarse grind at a P80 of approximately 750 microns;

· Rapid leach times - approximately 6 hours at Palacios and 12 hours at

Sageras;

· Leach temperature ambient;

· Low reagent consumptions at Sageras of 15-20 kg/t and moderate consumption

at Palacios;

· The tests are based on a simplified extraction flow sheet, similar to the

operational process steps utilized at the Quercus Plant;

· Minimal recovery of impurities with the acid leach;

· Reduction of environmental issues with the generation of "dry" leach

residue.

It is important to note that these results are preliminary and leach parameters

have not yet been optimized.

Phase 1 of the metallurgical test work is focusing on a production rate of 2.1

Mlbs (0.95 Kt) of U3O8 per annum using the Palacios and Sageras deposits as the

initial feed to the Quercus Plant.

However, test work has also commenced on Phase 2 which is reviewing the

production options ranging up to 5 Mlbs (2.3 Kt) of U3O8 per annum. Preliminary

bottle roll tests for Alameda South are very encouraging with uranium

extractions up to 91% and low acid consumption. These extraction levels are

consistent with previously reported extractions in excess of 90% from Retortillo

column leach tests in 2009.

Commenting on the above results, the Managing Director of Berkeley Resources Mr.

Ian Stalker said:

"These initial non-optimized results from the Palacios and Sageras deposits are

encouraging and assist in confirming the potential use of a dynamic leach

process using the Quercus Plant.

The preliminary bottle roll results from the Alameda South samples are equally

promising. This deposit, although not previously treated via the Quercus Plant,

has similar mineralogy to the Palacios and Sageras mineralisation and appears

likely to assist in maintaining a relatively low level of capital expenditure

going forward.

We have now commenced detailed metallurgical test work related to Phase 2 which

is based on developing both the Retortillo and Alameda South Deposits as

separate feed sources of concentrate following initial on-site treatment.

It is not anticipated that this additional metallurgical test work will impact

on plans to recommence mining operations at Salamanca, currently targeted for

the end of 2012."

Enquiries - Managing Director: Ian Stalker Tel: +34

608 221 497

RBC Capital Markets: Martin Eales Tel:

+44 20 7029 7881

Introduction

The Salamanca Uranium Project consists of four separate areas containing a

number of metasedimentary hosted uranium deposits located in the western part of

the Salamanca Province in Spain. These deposits are near surface accumulations

of open pittable uranium within close proximity to the Quercus uranium ore

processing plant.

Berkeley commenced a Feasibility Study in 2009 which was initially focused on

the Águila (Palacios and Sageras deposits) but has now been extended to include

the Alameda (Alameda South deposit) and Retortillo (Retortillo and Santidad

deposits) areas.

In February 2010, 2,000kg of representative samples taken from diamond drill

core was sent to the SGS Metallurgical Laboratories in Perth, Australia for a

comprehensive metallurgical test work campaign supervised by Aker Solutions and

Orway Mineral Consultants (WA) Pty Ltd. The material was selected on the basis

of lithology, oxidation and grade from the Sageras, Palacios and Alameda South

deposits (Table 1).

+----------+---------+--------+------+--------+------+-------+--------+

| Metallurgical test work sample composition- PALACIOS - |

| SAGERAS - ALAMEDA |

+---------------------------------------------------------------------+

| Deposit |Average | Grade of oxidation | | |

| name | grade | | | |

+----------+---------+-------------------------------+-------+--------+

| Hole | (ppm | partially | primary |TOTAL | % |

| ID's | U3O8) | oxidized | | | |

+----------+ +---------------+---------------+-------+ +

| | |weight | % |weight | | % |weight |

| | | (kg) | | (kg) | | | (kg) |

+----------+---------+--------+------+--------+------+-------+--------+

|PALACIOS | 200 - | 199 | 33% | 75 | 12% | 274 | 45% |

| | 300 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| Holes | 300 - | - | - | 75 | 12% | 75 | 12% |

|1-2-5-12 | 500 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| | > 500 | 263 | 43% | - | - | 263 | 43% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | 462 | 76% | 150 | 24% | 612 | 100% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| SAGERAS | | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| Holes | 200 - | 71 | 11% | 149 | 21% | 220 | 32% |

| 1-3-5 | 300 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| | 300 - | 190 | 27% | - | | 190 | 27% |

| | 500 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| | > 500 | 141 | 20% | 148 | 21% | 289 | 41% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | 402 | 58% | 297 | 42% | 699 | 100% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| ALAMEDA | | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| Hole 3 | 200 - | 172 | 27% | - | - | 172 | 27% |

| | 300 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| | 300 - | 214 | 33% | - | - | 214 | 33% |

| | 500 | | | | | | |

+----------+---------+--------+------+--------+------+-------+--------+

| | > 500 | 257 | 40% | - | - | 257 | 40% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | 643 |100% | - | - | 643 | 100% |

+----------+---------+--------+------+--------+------+-------+--------+

| | | 1508 | | 447 | | 1954 | 100% |

| | | kg | | kg | | kg | |

+----------+---------+--------+------+--------+------+-------+--------+

Table 1 - Metallurgical Test Work Samples

Current Work

The primary objective of the Phase 1 metallurgical test work currently being

undertaken at SGS is to optimise the process conditions for treating the uranium

ore lithologies at Sageras and Palacios in a tank leach configuration. The

results of the current work will be used for the re-commissioning of the Quercus

Processing Plant at a capacity of 2.1Mlbs (0.95 Kt) of U3O8 per annum.

Phase 2 of metallurgical test work has also commenced with the objective to

undertake test work on uranium ore lithologies from the satellite deposits of

Alameda South and Retortillo. This additional test work is examining uranium

concentration by either flotation or heap leaching and ion exchange with

possible eluate or resin transfer.

The Phase 1 test work campaign commenced in March 2010 and is scheduled to be

completed in the 3rd quarter 2010 with the following test work in progress:

· Preliminary mineralogy on the various ore types;

· Communition (crushing & grinding);

· Preliminary ore sorting;

· Flotation;

· Tank leaching;

· Heap leaching;

· Thickening and filtration;

· Solvent extraction;

· Geotechnical and geochemical testing of the final process residues, and

· Effluent neutralisation.

Initial Results

The current dynamic leach test work has delivered uranium extraction rates in

excess of 93% at Palacios and 87% at Sageras. All the tests to date have used a

coarse grind to the leach feed of P80 (750 microns) with the aim of minimising

energy requirements in the comminution circuit.

The leach times to achieve these extraction rates are relatively short from 6

hours at Palacios to 12 hours at Sageras.

The reagent consumption is low at Sageras which consumes 15 - 20 kg of acid per

tonne of ore and approximately double this at Palacios.

The tank leach test work completed to date has supported the conceptual flow

sheet using a relatively simple acid leach process common to many existing

uranium mines.

The Alameda South static heap leach test work program has commenced with a suite

of bottle roll leach tests as a precursor to future column tests. The

preliminary results are encouraging with extractions ranging up to 91% and acid

consumptions varying between 17 and 24 kg/tonne. These tests are continuing and

a comprehensive program of column leaching is planned to determine optimum leach

parameters.

Future Work

Phase 1 of the tank leach test work program is expected to be completed in the

3rd quarter 2010. Future work in the Phase 1 program of test work is aimed at:

· Optimising the ore sorting process.

· Determining optimal process conditions in dynamic leaching.

· Confirming the agitation system for a coarse grind to be employed in the

leach circuit.

· Optimising equipment selection for separating the leach residue from the

uranium rich leach liquors.

· Confirming requirements for a pre-concentration of liquors prior to

solvent extraction.

Additional representative drill core is currently being selected prior to

shipping to SGS for Phase 2 in order to better understand the communition and

ore sorting requirements and to provide additional material for column leach and

flotation test work.

The column leach and flotation test work will extend into 2011 with a view to

identifying the optimal concentration process for the satellite deposits of

Alameda South and Retortillo.

Preliminary engineering design will commence in June 2010 to develop the process

engineering data for the study.

A full version of this announcement including images can be downloaded from

Berkeley's website at www.berkeleyresources.com.au.

This information is provided by RNS

The company news service from the London Stock Exchange

END

MSCEAKKXESXEEEF

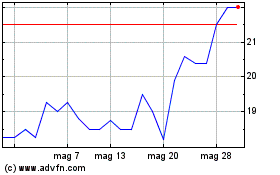

Grafico Azioni Berkeley Energia (LSE:BKY)

Storico

Da Giu 2024 a Lug 2024

Grafico Azioni Berkeley Energia (LSE:BKY)

Storico

Da Lug 2023 a Lug 2024