PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR) (OTCQX:

PYRGF) (FRA: 8PY), a high-tech company (the “Company” or

“PyroGenesis”) that designs, develops, manufactures and

commercializes advanced plasma processes and sustainable solutions

which are geared to reduce greenhouse gases (GHG) and address

environmental pollutants, is pleased to announce today that it has

been advised by its client, Progressive Planet, that the latest

series of compressive strength tests on its PozPyro green cement

additive product reveal impressive results, posting strength

comparisons significantly above the acceptable standard for similar

material. PozPyro enhances the strength of concrete as a

replacement for fly ash, which is in diminishing supply.

PozPyro, a cement alternative, is being

developed in collaboration with Progressive Planet as a

supplementary cementing material (SCM) designed to partially

replace traditional Portland Cement. Of note, Portland Cement emits

substantial amounts of CO2 during its production. PozPyro, on the

other hand, is created by using a PyroGenesis plasma-based process

that transforms quartz silica, a widely available material, into a

SCM (PozPyro), without off-gassing CO2 during the production

process. This innovation comes at a time when the cement industry

seeks more sustainable practices without compromising quality or

performance.

“Quartz silica is one of the most abundant

materials in the earth’s crust,” said P. Peter Pascali, President

and CEO of PyroGenesis. “The ability to economically convert it

into PozPyro could offer a new supply of material to compensate for

the diminishing supply of fly ash, a common SCM, which, by the way,

is generated by the same coal fired power plants which are being

targeted for shut down in Canada by 2030.”

According to Progressive Planet’s news release

today, concrete producers are looking for SCMs that (i) increase

the compressive strength of their mix while at the same time (ii)

lowering their carbon footprint without sacrificing

workability.

WORKABILITY

The workability of cement is measured by water

demand and is a measure of its ease of use in various concrete

applications. The smaller the water demand number, the better the

reading. A passing water demand number must be less than 115% of

the water demand of the control mix.

The water demand for PozPyro was between 99% and

109% for all test batches and as such PozPyro demonstrated

excellent workability.

STRENGTH ACTIVITY INDEX

(SAI)

The SAI is an industry standard for measuring

the compressive strength of cement mortar cubes. As announced in a

press release on April 11, 2024, the results of the 7-day testing

that showed an approximate average +45% SAI gain across four tests

against the minimum target value.

In the 28-day tests announced today, Portland

Cement was used as the control product, with varied compressive

strengths between 35.26 and 39.62 megapascals (MPa) depending on

the test.

These tests were conducted in two series, A and

B, with two tests in each series, using different input variables

to test for optimized results.

TESTING AGAINST MINIMUM COMPLIANCE (75%

PORTLAND CEMENT MPA)

For SAI tests, a cement additive product test is

acceptable at a minimum strength of 75% of the control product

strength.i For one Series B test, the Portland Cement control

achieved a compressive strength value of 36.18 MPa at 28 days. An

additive product would therefore be acceptable based on achieving

27.14 MPa (equating to 75% of the Portland Cement control

strength).

The results for the individual Series B test

showed a blend of Portland Cement containing 20% PozPyro far

surpassed this target, achieving a peak result of 54.15 MPa – a

result 99.56% higher than the minimum acceptable value.

The overall average gain for all tests in both

series A and B was +67.43% against the minimum compliant for an

acceptable cement additive product.

TESTING AGAINST MAXIMUM COMPLIANCE (100%

PORTLAND CEMENT MPA)

When compared to a 100% value of Portland Cement

alone, this same Series B PozPyro/Portland Cement blend test

surpassed even the full-strength value of the Portland Cement

control product by up to 49.67%.

The overall average gain for all tests in both

series A and B was +25% against the maximum product compliance for

an acceptable cement additive product. This result means

that the PozPyro material, when added to Portland Cement at a

20%/80% blend, outperformed a cement-only Portland Cement control

in strength tests by 25%.

“These 28-day test results confirm the

impressive results achieved by the previous 7-day tests, and

underscore yet again the potential transformative nature of plasma

in producing materials, in both an economically and environmentally

beneficial manner, that are key to heavy industry,” said P. Peter

Pascali, President and CEO of PyroGenesis. “Not only were we able

to far surpass the minimum acceptable product standard compared to

75% of the control, but when compared to a full value of the

control the PozPyro green cement additive showed a 49.67% gain. In

other words, these tests suggest that not only can PozPyro

potentially outperform other traditional cement additive products

in strength, it has the potential to directly outperform pure

cement alone. As I’ve stated before, the cement industry is a key

target for us, and we have high expectations for the PozPyro green

cement additive material.”

Image 1: A comparison of the four individual

Series A and Series B strength tests, measured at 7- and 28-days in

megapascals (MPa) of a 20% PozPyro/80% Portland Cement blend

against a 100% pure Portland Cement control, a 20% fly ash blend, a

20% ground granulated blast-furnace slag (GGBFS) blend, and a 20%

silica fume blend produced using traditional methods.

Steve Harpur, CEO of Progressive Planet,

commented on the results over the last month during which

Progressive Planet prepared four separate batches of cement mortar

cubes to test, under the American Society for Testing and Materials

(“ASTM”) testing protocol, at both 7 and 28 days for compressive

strength: “These results were exceptional and provide us the

technical confidence to take the next steps to bring this product

to market. In the Pacific Northwest alone, over one million tons of

fly ash will cease to be generated by the summer of 2025 at which

time two massive thermal coal to energy facilities will have

finished converting from burning coal to natural gas.”

Image 2: A comparison of the Series A and Series

B strength tests, measured at 7- and 28-days in megapascals (MPa)

of a 20% PozPyro/80% Portland Cement blend, using averages of each

of two tests within both Series A and Series B, against 100% pure

Portland Cement control, 20% fly ash blend, 20% ground granulated

blast-furnace slag (GGBFS) blend, and 20% silica fume blend.

CO2

EMISSIONS / LACK THEREOF

While compressive strength is key to overall

product viability, the reduction of CO2 emissions achieved by using

PyroGenesis’ plasma technology, a low carbon emitting process, has

the potential to offer further “green” benefits.

CO2 emissions within a product lifecycle are

defined globally within 3 categories: Scope 1, Scope 2, and

Scope.

Generally speaking:

- Scope 1 emissions are direct

greenhouse gas emissions caused by the company’s production

processes.

- Scope 2 emissions are indirect

emissions, that factors in the use of energy purchased externally

(and the CO2 created as a result of that energy being originally

produced).

- Scope 3 emissions represent the CO2

emissions from operations upstream and downstream of the company’s

operations, such as raw material production, transportation, waste,

and end of life remediation.

When compared to other traditional cement

additives, the production of PozPyro may result in dramatically

lower CO2 emissions. For the purposes of the graph below, Scope 2

emissions regarding electricity usage have been factored into

PozPyro’s emission level. Without these Scope 2 emissions, the

greenhouse gas emissions released during the production of PozPyro

may be virtually zero.

Image 3: A comparison of CO2 emitted during the

production of 1 tonne of PozPyro vs. other cement additive

products. CO2 emission assigned to PozPyro comes from production of

electricity subsequently used by the process, not from the process

itself.

“These are the best results we have ever seen in

an alternative cementing material. The fact that silica-based

cements do not off gas CO2 is an additional bonus to the

exceptional compressive strength results,” added Steve Gurney,

President of Progressive Planet.

Image 4: A zero-CO2, energy-efficient conversion

of crystalline quartz to amorphous silica through PyroGenesis’

plasma process.

POTENTIAL ADRESSABLE MARKET

According to Progressive Planet’s press release

of today, it was noted that the North American cement market size

reached 194.2 million US tons in 2023, and they expect that it will

reach 279.8 million tons by 2032, reflecting an annual growth rate

of 4% between 2024 and 2032. Assuming that pozzolanic cements could

be a substitute for 20% of Portland Cement, the total addressable

North American market is projected to reach over 55 million tons by

2032. At a projected price of US$200 per ton by 2032, the potential

market is over $11 billion USD per annum by that time.

NEXT STEPS: PILOT PLANT

Now that the compressive strength of PozPyro has

been validated, the next critical step is to progress towards the

Pilot Plant stage. In preparation for this phase, an engineering

feasibility study will be conducted over the next several months.

This comprehensive study will focus on quantifying various critical

elements to ensure the economic viability of the pilot plant

operations. Key considerations will include maximizing heat

recovery and other efficiency metrics, which are essential for

sustainable and cost-effective production.

We are committed to rigorous evaluation and

optimization processes, aiming to address all technical and

economic aspects of the pilot plant. Updates on our progress and

findings from the feasibility study will be provided in due course,

as we move closer to achieving a fully operational pilot plant that

meets our high standards for innovation and efficiency.

PyroGenesis’ involvement in developing PozPyro

from quartz is part of PyroGenesis’ three-tiered solution

ecosystem that aligns with economic drivers that are key to

global heavy industry. PozPyro is part of PyroGenesis’ Commodity

Security & Optimization tier, where the recovery of viable

metals and the optimization of production to increase output helps

to maximize raw materials and improve the availability of critical

minerals.

About PyroGenesis Canada

Inc.

PyroGenesis Canada Inc., a high-tech company, is

a proud leader in the design, development, manufacture and

commercialization of advanced plasma processes and sustainable

solutions which reduce greenhouse gases (GHG) and are economically

attractive alternatives to conventional “dirty” processes.

PyroGenesis has created proprietary, patented and advanced plasma

technologies that are being vetted and adopted by multiple

multibillion dollar industry leaders in four massive markets: iron

ore pelletization, aluminum, waste management, and additive

manufacturing. With a team of experienced engineers, scientists and

technicians working out of its Montreal office, and its 3,800 m2

and 2,940 m2 manufacturing facilities, PyroGenesis maintains its

competitive advantage by remaining at the forefront of technology

development and commercialization. The operations are ISO 9001:2015

and AS9100D certified, having been ISO certified since 1997. For

more information, please visit: www.pyrogenesis.com.

About Progressive Planet

Progressive Planet is a CleanTech and

manufacturing company with proven product lines based

in Kamloops, British Columbia. The company’s expertise lies in

developing critical low-carbon and carbon sequestering solutions

using our owned mineral assets and recycled materials to create

planet-friendly products that fight climate change and protect our

planet's health.

Progressive Planet products are in 10,000+

retail stores across North America. Progressive Planet’s

innovations, created at their C-Quester™ Centre of Sustainable

Innovation, bring positive disruption to the cement, agricultural

and animal-care sectors.

Cautionary and Forward-Looking

Statements

This press release contains “forward-looking

information” and “forward-looking statements” (collectively,

“forward-looking statements”) within the meaning of applicable

securities laws. In some cases, but not necessarily in all cases,

forward-looking statements can be identified by the use of

forward-looking terminology such as “plans”, “targets”, “expects”

or “does not expect”, “is expected”, “an opportunity exists”, “is

positioned”, “estimates”, “intends”, “assumes”, “anticipates” or

“does not anticipate” or “believes”, or variations of such words

and phrases or state that certain actions, events or results “may”,

“could”, “would”, “might”, “will” or “will be taken”, “occur” or

“be achieved”. In addition, any statements that refer to

expectations, projections or other characterizations of future

events or circumstances contain forward-looking statements.

Forward-looking statements are not historical facts, nor guarantees

or assurances of future performance but instead represent

management’s current beliefs, expectations, estimates and

projections regarding future events and operating performance.

Forward-looking statements are necessarily based

on a number of opinions, assumptions and estimates that, while

considered reasonable by the Company as of the date of this

release, are subject to inherent uncertainties, risks and changes

in circumstances that may differ materially from those contemplated

by the forward-looking statements. Important factors that could

cause actual results to differ, possibly materially, from those

indicated by the forward-looking statements include, but are not

limited to, the risk factors identified under “Risk Factors” in the

Company’s latest annual information form, and in other periodic

filings that the Company has made and may make in the future with

the securities commissions or similar regulatory authorities, all

of which are available under the Company’s profile on SEDAR+ at

www.sedarplus.ca. These factors are not intended to represent a

complete list of the factors that could affect the Company.

However, such risk factors should be considered carefully. There

can be no assurance that such estimates and assumptions will prove

to be correct. You should not place undue reliance on

forward-looking statements, which speak only as of the date of this

release. The Company undertakes no obligation to publicly update or

revise any forward-looking statement, except as required by

applicable securities laws.

Neither the Toronto Stock Exchange, its

Regulation Services Provider (as that term is defined in the

policies of the Toronto Stock Exchange) nor the OTCQX Best Market

accepts responsibility for the adequacy or accuracy of this press

release.

For further information please contact: Rodayna

Kafal, Vice President, IR/Comms. and Strategic BDE-mail:

ir@pyrogenesis.com http://www.pyrogenesis.com

Images accompanying this announcement are available

at:https://www.globenewswire.com/NewsRoom/AttachmentNg/e7927011-62b4-476f-b155-1a2ba79ac776https://www.globenewswire.com/NewsRoom/AttachmentNg/e9166c75-8f46-4dff-85c8-429d193036a2https://www.globenewswire.com/NewsRoom/AttachmentNg/161e5fa6-8a35-4b6b-b695-812373c63829https://www.globenewswire.com/NewsRoom/AttachmentNg/9a2b016c-c7be-4dff-8c19-4705685a25efhttps://www.pyrogenesis.com/wp-content/uploads/2024/04/pyrogenesis-quartz-to-amorphous-silica.png

References[1]

Lo, F. C., Lee, M. G., & Lo, S. L. (2021).

Effect of coal ash and rice husk ash partial replacement in

ordinary Portland cement on pervious concrete. Construction

and Building Materials, 286, 122947.[2]

Kathirvel, P., & Murali, G. (2023). Effect of

using available GGBFS, silica fume, quartz powder and steel fibres

on the fracture behavior of sustainable reactive powder

concrete. Construction and Building Materials, 375,

130997.[3] Uddin, M. A., Bashir, M. T., Khan, A.

M., Alsharari, F., Farid, F., & Alrowais, R.

(2023). Effect of Silica Fume on Compressive

Strength and Water Absorption of the Portland Cement–Silica Fume

Blended Mortar. Arabian Journal for Science and Engineering,

1-9.[4] Sævarsdottir, G., Kvande, H., &

Magnusson, T. (2021). Greenhouse gas emissions

from silicon production-development of carbon footprint with

changing energy systems. In Proceedings of the 16th

International Ferro-Alloys Congress (INFACON

XVI).[5] Manjunatha, M., Preethi, S., Mounika, H.

G., & Niveditha, K. N. (2021). Life cycle

assessment (LCA) of concrete prepared with sustainable cement-based

materials. Materials Today: Proceedings, 47,

3637-3644.[6] Habert, G., Miller, S. A., John, V.

M.,Provis, J. L., Favier, A., Horvath, A., & Scrivener, K. L.

(2020). Environmental impacts and decarbonization

strategies in the cement and concrete industries. Nature

Reviews Earth & Environment, 1(11), 559-573.

i https://www.astm.org/c0618-12.html

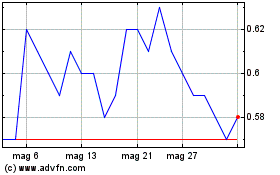

Grafico Azioni PyroGenesis (TSX:PYR)

Storico

Da Dic 2024 a Gen 2025

Grafico Azioni PyroGenesis (TSX:PYR)

Storico

Da Gen 2024 a Gen 2025