PyroGenesis Inc. (“PyroGenesis”) (http://pyrogenesis.com) (TSX:

PYR) (OTCQX: PYRGF) (FRA: 8PY1), a high-tech company that designs,

develops, manufactures and commercializes all-electric plasma

processes and sustainable solutions to support heavy industry in

their energy transition, emission reduction, commodity security,

and waste remediation efforts, announces today that, further to HPQ

Silicon Inc’s (“HPQ”) press release dated today, and PyroGenesis’

own news releases dated February 6, 2024 and March 12, 2024, the

next milestone for the fumed silica reactor (“FSR”) pilot plant has

been reached, with its successful week-long operation and the

production of the first batch of materials. This initial test was

designed to evaluate the system’s ability to precisely regulate the

feedstock thermal profile, encompassing pre-heating, controlled

heating rates, and stabilization at target operational parameters

required for fumed silica synthesis.

The material produced was visually analyzed and

confirmed to be consistent with material seen in the previous

lab-scale production. Comprehensive analysis will be conducted at

an independent laboratory, to verify structural and chemical

properties with more quantitative data, and to validate product

quality, all of which will be used for next step process

optimization related to further tests. Of note, the FSR pilot plant

is a 20-fold scale up of the lab-scale system. The next three batch

tests will focus on achieving consistent and repeatable production

of high-surface-area fumed silica, ensuring that product

specifications align with or exceed those achieved at lab

scale.

"Since 1944, the fumed silica industry has

relied on the same conventional, fossil-fuel-intensive production

methods. At PyroGenesis, we are committed to breaking that cycle

through innovation," said P. Peter Pascali, President and CEO of

PyroGenesis Inc. "The fumed silica reactor represents a potentially

revolutionary shift – scaling up a plasma-based process that

eliminates carbon emissions while maintaining superior product

quality. By decarbonizing this industry, we are not just enhancing

efficiency; we are aiming to a new standard for sustainable,

commercially viable fumed silica production, empowering clients

with a cleaner and more reliable process."

The FSR technology project is being conducted in

conjunction with HPQ Silica Polvere Inc. (“HPQ Polvere”), a wholly

owned subsidiary of HPQ. PyroGenesis previously announced in a

press release dated May 30, 2024, its intent to exercise its right

to convert its annual royalty rights into a 50% ownership stake of

HPQ Polvere pursuant to a design and development agreement.

Fumed silica is a moisture-absorbing white

microstructure powder with high surface area and low bulk density.

Used most often as a thickening agent, anti-caking agent, and

stabilizer to improve the texture and consistency of products, the

commercial applications of fumed silica can be found in many

industries across thousands of product lines, including – but not

limited to – personal care, powdered food, pharmaceuticals,

agriculture (food & feed), adhesives, paints, sealants,

construction, batteries and automotive.

In the FSR project, PyroGenesis is the exclusive

supplier of a technology capable of using quartz (SiO2) as a raw

material to produce commercial-grade fumed silica in a single and

eco-friendly step while eliminating the use of harmful chemicals

generated by conventional methods.i The FSR pilot plant, if

successful, could provide a groundbreaking contribution to the

repatriation of silica production to North America.

On July 9, 2024, PyroGenesis announced that HPQ

Polvere had signed a letter of intent with Evonik Corporation, a

global specialty chemicals company. The objective of HPQ Polvere’s

letter of intent with Evonik is to outline the basis of

collaboration during the FSR pilot scale phase with the goal to

validate the ability of the FSR to produce low-cost, low-carbon

material acceptable to Evonik’s specifications.

The FSR pilot plant exists within a dedicated

space inside PyroGenesis’ facilities, with a custom-designed

infrastructure that meets the pilot plant’s unique ventilation,

safety, and access requirements. A 4,000 sq ft facility with a

30-foot height allowance was allocated to house the pilot plant,

which itself has an approximate layout footprint of 50ft by 30ft.

The FSR pilot plant has a 50 TPY output capacity.

In addition, results announced by PyroGenesis

(refer to the Company’s news release dated January 11, 2024) from

an internal economic and technical study, which was carried out at

the request of a third-party who requested confidentiality,

confirmed the viability of, and advantages from, the eventual scale

up to a 1,000 TPY commercial configuration. These advantages

included potential EBIDTA margins three times higher than the

industry average of 20%, and a capital investment 93% less than

that required for building a conventional fumed silica plant.

ii

The fumed silica market, valued at US$1.3

billion in 2022, is expected to grow at a CAGR of 5% to reach

US$2.1 billion by 2032. Fumed silica sales accounted for almost 23%

of the global specialty silica market at the end of 2021. iii

PyroGenesis’ involvement in developing fumed

silica from quartz is part of its three-vertical solution ecosystem

that aligns with economic drivers that are key to global heavy

industry. Metal powders are part of PyroGenesis’ Commodity

Security & Optimization vertical, where the

development of advanced material production techniques, and the use

of technology such as plasma to recover viable metals, chemicals,

and minerals from industrial waste, helps to maximize raw materials

and improve the availability of critical minerals. Titanium has

been identified as a critical mineral by the Canadian government.

The Company’s other verticals are Energy Transition and

Emission Reduction and Waste

Remediation.

About PyroGenesis Inc.

PyroGenesis, a high-tech company, is a proud

leader in the design, development, manufacture and

commercialization of advanced plasma processes and sustainable

solutions which reduce greenhouse gases (GHG) and are economically

attractive alternatives to conventional “dirty” processes.

PyroGenesis has created proprietary, patented and advanced plasma

technologies that are being vetted and adopted by multiple

multibillion dollar industry leaders in four massive markets: iron

ore pelletization, aluminum, waste management, and additive

manufacturing. With a team of experienced engineers, scientists and

technicians working out of its Montreal office, and its 3,800 m2

and 2,940 m2 manufacturing facilities, PyroGenesis maintains its

competitive advantage by remaining at the forefront of technology

development and commercialization. The operations are ISO

9001:2015 and AS9100D certified, having been ISO certified since

1997. PyroGenesis’ shares are publicly traded on the TSX in Canada

(TSX: PYR), the OTCQX in the US (OTCQX: PYRGF), and the Frankfurt

Stock Exchange in Germany (FRA: 8PY1).

About HPQ Silicon

|

HPQ activities are centred around the following five (5)

pillars: |

|

(1) |

Becoming a green low-cost (Capex and Opex) manufacturer of Fumed

Silica using the FUMED SILICA REACTOR, a proprietary technology

owned by HPQ Silica Polvere Inc being developed for HSPI by

PyroGenesis. |

|

(2) |

Becoming a producer of silicon-based anode materials for battery

applications with the assistance of NOVACIUM SAS. |

|

(3) |

HPQ SILICON affiliate NOVACIUM SAS is developing a low carbon,

chemical based on demand and high-pressure autonomous hydrogen

production system. |

|

(4) |

HPQ SILICON affiliate NOVACIUM SAS is developing a new process to

transform black aluminium dross into a valuable resource. |

|

(5) |

Becoming a zero CO2 low-cost (Capex and Opex) producer of High

Purity Silicon (2N+ to 4N) using our PUREVAPTM “Quartz Reduction

Reactors” (QRR), a proprietary technology owned by HPQ being

developed for HPQ by PyroGenesis. |

| |

|

For more information, please visit HPQ Silicon

web site.

Cautionary and Forward-Looking

Statements

This press release contains “forward-looking

information” and “forward-looking statements” (collectively,

“forward-looking statements”) within the meaning of applicable

securities laws. In some cases, but not necessarily in all cases,

forward-looking statements can be identified by the use of

forward-looking terminology such as “plans”, “targets”, “expects”

or “does not expect”, “is expected”, “an opportunity exists”, “is

positioned”, “estimates”, “intends”, “assumes”, “anticipates” or

“does not anticipate” or “believes”, or variations of such words

and phrases or state that certain actions, events or results “may”,

“could”, “would”, “might”, “will” or “will be taken”, “occur” or

“be achieved”. In addition, any statements that refer to

expectations, projections or other characterizations of future

events or circumstances contain forward-looking statements.

Forward-looking statements are not historical facts, nor guarantees

or assurances of future performance but instead represent

management’s current beliefs, expectations, estimates and

projections regarding future events and operating performance.

Forward-looking statements are necessarily based

on a number of opinions, assumptions and estimates that, while

considered reasonable by PyroGenesis as of the date of this

release, are subject to inherent uncertainties, risks and changes

in circumstances that may differ materially from those contemplated

by the forward-looking statements. Important factors that could

cause actual results to differ, possibly materially, from those

indicated by the forward-looking statements include, but are not

limited to, the risk factors identified under “Risk Factors” in

PyroGenesis’ latest annual information form, and in other periodic

filings that it has made and may make in the future with the

securities commissions or similar regulatory authorities, all of

which are available under PyroGenesis’ profile on SEDAR+ at

www.sedarplus.ca. These factors are not intended to represent a

complete list of the factors that could affect PyroGenesis.

However, such risk factors should be considered carefully. There

can be no assurance that such estimates and assumptions will prove

to be correct. You should not place undue reliance on

forward-looking statements, which speak only as of the date of this

release. PyroGenesis undertakes no obligation to publicly update or

revise any forward-looking statement, except as required by

applicable securities laws.

Neither the Toronto Stock Exchange, its

Regulation Services Provider (as that term is defined in the

policies of the Toronto Stock Exchange) nor the OTCQX Best Market

accepts responsibility for the adequacy or accuracy of this press

release.

For further information please contact:Rodayna Kafal, Vice

President, IR/Comms. and Strategic BDE-mail: ir@pyrogenesis.com

http://www.pyrogenesis.com

i 2012 – Executive summary: “SILICON-CHEMISTRY CARBON BALANCE,

AN ASSESSMENT OF GREENHOUSE GAS EMISSIONS AND REDUCTIONS”, Covering

the Production, Use and End-of-Life of Silicones, Siloxanes and

Silane Products in Europe, North America, and Japan. [Pages 20 to

21] (Commissioned by Global Silicones Council, Centre Européen des

Silicones, Silicones Environmental, Health and Safety Council of

North America Silicone Industry Association of Japan).

ii Traditional Fumed Silica manufacturing

involves a complex three-step process:

Step 1: Conversion of Quartz to Silicon Metal

(Si), with an average Capex of around US$9.38 per kilogram of

annual capacity (for reference, the PCC BakkiSilicon Plant in

Iceland cost US$300 million for an annual capacity of 32,000

tonnes).

Step 2: Conversion of Si to Silicon

Tetrachloride (SiCl4), with an average Capex of approximately

US$125.00 per kilogram of annual capacity (e.g., Wacker Chemie AG

Polysilicon's US production plant cost US$2.5 billion for an annual

capacity of 20,000 tonnes).

Step 3: Burning Silicon Tetrachloride (SiCl4)

with Hydrogen and Oxygen to produce Fumed Silica (SiO2), incurring

an average Capex of around US$11.54 per kilogram of annual capacity

(Wacker Chemie AG's US Fumed Silica plant cost US$150 million for

an annual capacity of 20,000 tonnes). The combined Capex for these

three steps averages at US$145.92 per kilogram of annual capacity.

According to a rough order of magnitude study by PyroGenesis, our

one-step process for making Fumed Silica is estimated to have an

average Capex per kilogram of annual capacity between US$9.00 and

US$10.00, which is approximately 93% less than traditional

processes.

iii

https://www.factmr.com/report/2301/fumed-silica-market

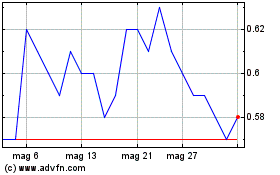

Grafico Azioni PyroGenesis (TSX:PYR)

Storico

Da Feb 2025 a Mar 2025

Grafico Azioni PyroGenesis (TSX:PYR)

Storico

Da Mar 2024 a Mar 2025