Aquafil – Helping Define the Circular Business Model of the Future

20 Giugno 2024 - 4:17PM

Aquafil SpA (ECNLF:OTCQX – ECNL:IM), based in Arco

(TN) Italy and a pioneer of the circular economy, believes now is

the time for business leaders to make a radical shift. If we are to

continue driving toward a circular economy, businesses must think

beyond how they can create circular products and also begin

developing and adopting circular business models.

There is especially an opportunity for this

shift within the interior design and architecture space, where

products and materials are frequently used and switched out. The

common business model in today’s design industry still struggles to

create with the end in mind: spaces are created to be used for a

specific purpose and not optimized to be re-used again. Research

from LMN Architects recently discovered that this cycle of waste

has built a cumulative carbon impact that is even greater than the

emissions generated by the structure of the building itself.

By transitioning to innovative business models

with a circular focus, design businesses will still be able to

share important products with customers while reducing resource

extraction on one end and waste buildup on the other. Some of the

circular business models of the future that we’re starting to see

are products as services, product use extension and take-back

programs.

Products as Services

One of the latest innovative business models

we’re seeing is one where items that were typically sold as

products are now being sold as services. The Ellen MacArthur

Foundation highlights a few organizations practicing this model,

from lighting-as-a-service, where customers pay a monthly fee for

light while the business manages the installation, operation and

maintenance of the lighting systems, to furniture-as-a-service,

where customers pay a monthly fee for furniture and return it when

no longer needed.

These service models enable customers to keep up

with the latest and greatest products without contributing to

waste. Businesses are able to take back the products when they

start to wear and tear or the customer no longer needs them,

finding ways to reuse the materials or get them ready for a new

customer. The success of the business changes from volume to

performance, therefore extending the life of the product. This

mindset shift will also mean a shift in the way products are

designed, as designers and manufacturers are incentivized to create

products that are longer lasting and use ingredients that withstand

wear and tear for longer. Businesses that turn to the product as a

service model will have to consider the durability and impact of

the materials they work with in a way they hadn’t before.

Product Use Extension

Another circular business model explores

opportunities to extend the life of a product after its use. In the

architecture and construction space, this can mean finding ways to

renovate existing spaces with existing materials rather than

bulldozing and starting fresh. A recent Bloomberg article

highlights how the U.S. economy is already moving in this direction

as renovations have overtaken new construction in architectural

billings for the first time in 20 years.

Architects are typically inspired to create

something new, but there needs to be a shift in excitement to

transform older buildings just as well, especially with a circular

mindset. Not only does it create more carbon emissions when we

build a new structure, there are also outdated energy systems and

embodied carbon within materials of older buildings that contribute

nearly 40% of total global greenhouse gas emissions, according to

the Global Alliance for Building and Construction. Architects have

the opportunity and responsibility to apply circular design

principles to already built environments in order to combat these

issues and extend the life of their products: in this case,

buildings.

For interior design, product use extension can

mean creating modular products that can easily be taken apart.

Take-Back Programs

Take-back programs will likely be the easiest

transition for traditional business models into more circular

practices, although they will require innovative logistics. Often,

organizations with this model have developed a way to reutilize the

materials from used products to create new products, enabling the

business to rely less on resource extraction. It also tends to

build a strong loyalty with customers who have an incentive to

continue buying products, knowing they will either be able to trade

it in for a newer model or receive a payment of some kind.

The take-back model has already been adopted

within the fashion industry, especially with businesses that are

already using recycled and regenerated ingredients in their design.

However, there is an opportunity for the design industry to also

utilize this model. For example, Aquafil’s carpet recycling centers

have provided Aquafil a way to take back nylon-based products like

carpet and fabric scraps that would otherwise end up in landfills

to create ECONYL® regenerated nylon. In states like California and

now New York with carpet recycling laws, businesses are even

incentivized to recycle their carpet, benefitting the recycler, the

business receiving the recycled materials as well as the

environment.

Building a Circular Business

Model

Moving from a linear to a circular economic

model brings multiple benefits, including the reduction of pressure

on the environment, the optimization of the availability of raw

materials and an inevitable boost to innovation and economic

growth. The companies that lead the way with circular business

models have given us an example of what is possible and an

inspiring hope for our future economy.

Over 10 years ago Aquafil recognized the virtue

and value of the Circular Economy and eco-design. Since then, the

Company has invested hundreds of millions of Euros in developing

technologies and building facilities to produce an infinitely

recyclable version of Nylon 6: ECONYL® regenerated nylon. The

latter maintains the same quality level and performance as standard

nylon, has the same wearing features as material from fossil fuel

and can help you closing the loop.

Today, Aquafil generates over 52% of its fibers

revenues from the ECONYL® regeneration products (1Q 2024 revenues

amounted to Euro 147.5 mln). The goal is to continually increase

this proportion targeting 60% to 2025.

About Aquafil SpA

Since 1965, the Aquafil Group has been a pioneer

of the circular economy and a landmark in terms of quality and

product innovation for Italy and the globe. We primarily

manufacture Nylon 6 fibers and polymers but also Nylon 6.6 and

Dryarn. Our flagship product is ECONYL® nylon, which revolutionizes

the world of synthetic fibers through a closed-loop model.

Today, Aquafil remains a leader in the research

of new production systems for sustainable development.

To keep current on Aquafil, please go to

www.aquafil.com.

Investors ContactGiulia Rossi

investor.relations@aquafil.commob: +39 327 0820.268

Media Contact Maria Giovanna

Sandrini maria.giovanna.sandrini@aquafil.commob: +39 348

6019.628

U.S. Contact:Joe

Hassettjoeh@gregoryfca.com610-787-0464 (Cell)

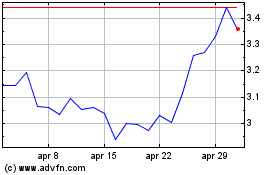

Grafico Azioni Aquafil (BIT:ECNL)

Storico

Da Feb 2025 a Mar 2025

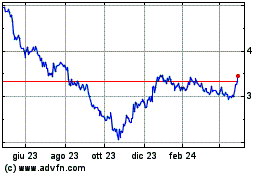

Grafico Azioni Aquafil (BIT:ECNL)

Storico

Da Mar 2024 a Mar 2025