Regulatory News:

Hoffmann Green Cement Technologies (Paris:ALHGR):

The VALOREM Group, a pioneering independent producer of green

energy in France, and Hoffmann Green Cement Technologies, an

industrial player committed to decarbonizing the construction

sector by designing and marketing innovative clinker-free cements,

announce the pouring of the world's first wind turbine foundation

made from 0% clinker decarbonized concrete.

On the site of the Plaine des Moulins wind farm in Jazeneuil

(Vienne), the VALOREM Group wanted Hoffmann Green and its partners

to achieve a world first: the pouring of a wind turbine foundation

using 630 m3 of decarbonated concrete. The use of decarbonated

concrete resulted in a saving of 33 tonnes of CO2, i.e. 32% less

than with traditional concrete, and this without any change in

construction methods.

This achievement is all the more remarkable in that it concerns

a very demanding application, where pouring is carried out in a

single operation, with a very high density of reinforcement to

ensure the durability of this type of structure.

The Plaine des Moulins wind farm will comprise 5 wind turbines,

each 180 metres high at the blade tip, with a total installed

capacity of 18 MW, and will generate around 42 GWh of green

electricity, equivalent to 18.6% of the electricity consumption of

the Haut Poitou community. The wind farm is scheduled for

commissioning in early 2025.

Baptiste WALYN, Director of VALREA, VALOREM Group's

construction subsidiary, underlines: « The VALOREM Group is

delighted with this world first. Wind turbine foundations are often

the target of misinformation. While steel-reinforced concrete is

non-polluting for the soil, and while all wind turbine foundations

are removed at the end of the park's life and the concrete

recycled, we are also proving today that innovation can

significantly reduce their carbon impact on the park's overall

carbon footprint. The VALOREM Group is a company with a mission,

resolutely committed to reducing all its impacts ».

Julien Blanchard and David Hoffmann, co-founders of Hoffmann

Green Cement Technologies, said: “We are very proud to be part

of this world premiere: the pouring of the first wind turbine

foundation using clinker-free decarbonized concrete. This

achievement represents a key milestone for Hoffmann Green and

strengthens our position on the wind energy market within the

strategic renewable energy sector. This achievement is in line with

our partnership signed with Biobuild in October 2022. It will

enable us to promote eco-responsible construction methods while

guaranteeing the quality of the foundations, as part of our common

commitment to the ecological transition.”

Under the Energy and Climate Act, France aims to achieve a 33%

share of renewable energy in gross final energy consumption by

2030. The renewable energy market therefore represents a key growth

potential in which Hoffmann Green intends to strengthen its

position. In the wind energy market segment, almost 300 projects

are expected to be deployed in the medium term.

Many committed players.

Prior to this historic premiere, 5 years of testing were

required to assess the performance, durability and safety of H-UKR

cement and concrete. The Appréciations Techniques d'Expérimentation

(ATEx) issued by the Centre Scientifique et Technique du Bâtiment

(CSTB) are the result of this in-depth work, and cover complex

technical issues such as dimensioning under heavy load, which is

essential for wind turbine foundations.

In addition to the test phase, ongoing technical exchanges have

been held with the various partners, from the dimensioning of the

wind turbine foundation by CTE Wind to the calibration of the

concrete formulation, and the performance of suitability tests and

a prototype with the RBS and Lepine TP teams.

Mélaine Besse, Président of BioBuild, also said:

«Reducing the carbon footprint of renewable energy projects is

essential both for the image of our industries and for the

ecological transition overall. As the company responsible for

strategic studies and analyses, it was natural for BioBuild to join

forces with Hoffmann, with whom we share a common vision in favour

of eco-sustainable construction ».

Emmanuel Hamon, Senior site supervisor and Mickaël Leray,

Branch Manager at Lépine TP - Groupe Angevin, commented: «The

Groupe Angevin is involved in hydraulic civil engineering (waste

water, drinking water) and civil engineering structures (PS, PI,

small viaducts, wind farms, etc.). We immediately agreed to take

part in this sustainable project in order to bring our expertise in

the specific techniques required for this kind of project ».

Frédéric Limouzin, Concrete Sector Manager at RBS - CMGO,

stated: «The core business of Carrières et Matériaux du Grand Ouest

(CMGO) is the operation of quarries and concrete plants, as well as

the production, recovery, recycling and sale of sand and gravel. As

the first link in the construction chain, we are delighted to have

been associated with this iconic project in the Grand Ouest region,

which promotes environment-friendly construction ».

Eric LEBRE, Sales Director of CHRYSO/GCP added: «The

CHRYSO®Enviromix ULC 5500 technology developed specifically for the

H-UKR binder enabled RBS - CMGO to ensure quality and consistency

of manufacture throughout the duration of the Jazeneuil wind

turbine foundation project. Like Hoffmann, we are convinced that

innovation has a major role to play in creating the materials of

tomorrow ».

Thanh Binh Tran, Technical Director of CTE Wind

concluded: «As an engineering and consultancy company specialised

in the design of foundations for wind turbines, CTE Wind has

designed almost 30,000 foundations for 2,500 wind farms since it

was founded. This first project using 0% clinker concrete, which

reduces CO2 emissions, represents a strategic turning point in the

fast-growing renewable energy market ».

ABOUT HOFFMANN GREEN CEMENT TECHNOLOGIES

Founded in 2014 and based in Bournezeau (Vendée, Western

France), Hoffmann Green Cement Technologies designs, produces and

distributes innovative extremely low-carbon cements – with a carbon

footprint 5 times lower than traditional cement – that present, at

equivalent dosage and with no alteration to the concrete

manufacturing process, superior performances than traditional

cement.

Hoffmann Green operates two production units powered by a solar

tracker park on the Bournezeau site: a 4.0 factory and H2, the

world's first vertical cement plant inaugurated in May 2023. A

third factory will be established at the Grand Port of Dunkirk in

2025, bringing the total production capacity to 550,000 tons per

year, representing 3% of the French market. The group has

industrialized a genuine technological breakthrough based on

modifying cement composition and creating a cold manufacturing

process, with 0% clinker and low energy consumption, making it a

leading and unique player in the cement market that has not evolved

for 200 years.

In a context of climate urgency and energy price inflation,

Hoffmann Green Cement actively participates in energy transition by

producing clean cement that consumes 10 to 15 times less energy

than Portland cement. It also promotes eco-responsible construction

and encourages circular economy and natural resource preservation.

With its unparalleled and constantly evolving technological

expertise, driven by high-performing teams, Hoffmann Green Cement

Technologies serves all markets in the construction sector, both in

France and internationally. Hoffmann Green was selected among the

2022 promotion of the top 20 French green startups as part of the

French Tech Green20 program, led by the French Tech Mission in

partnership with the Ministry of Ecological Transition. In June

2023, the company was selected for French Tech 2030, a new

ambitious support program operated by the French Tech Mission

alongside the General Secretariat for Investment (SGPI) and

Bpifrance. The company continues its international development with

contract signings in the United Kingdom, Belgium, Switzerland,

Saudi Arabia and recently in the United States. For further

information, please go to: www.ciments-hoffmann.fr/

ABOUT VALOREM

The VALOREM Group is an independent French operator in the field

of green energy, with expertise in the entire process of harnessing

renewable energies, from development to operation and maintenance,

including project management, construction and auditing services. A

wind power pioneer in France, VALOREM employs nearly 500 people and

is also present in Finland, Greece, Poland and Sweden. Since its

creation in 1994, the group has financed over 837 MW and has a

portfolio of 5.7 GW of projects under development. In 2022, its

assets generated 1.1 TWh of green electricity.

As a company with a mission, VALOREM's raison d'être is to

"harness local energies together, to pave the way for a sustainable

future based on solidarity".

VALOREM is certified ISO 9001 - quality, ISO 14001 -

environment, and ISO 45001 - occupational health and safety. In

2022, VALOREM was awarded the "Relations Fournisseurs et Achats

Responsables" label by the Conseil National des Achats.

www.valorem-energie.com

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240616753950/en/

CONTACTS HOFFMANN GREEN Hoffmann Green Jérôme

Caron Chief Financial Officer finances@ciments-hoffmann.fr 02 51

460 600

NewCap Investors Relations Thomas Grojean Alban Dufumier

ciments-hoffmann@newcap.eu 01 44 71 94 94

NewCap Medias Relations Nicolas Merigeau Antoine Pacquier

ciments-hoffmann@newcap.eu 01 44 71 94 98

Contact VALOREM Camille GIRARD Head of

Communication 06 46 30 71 85 camille.girard@valorem-energie.com

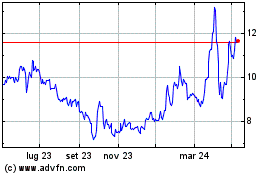

Grafico Azioni Hoffmann Green Cement Te... (EU:ALHGR)

Storico

Da Nov 2024 a Dic 2024

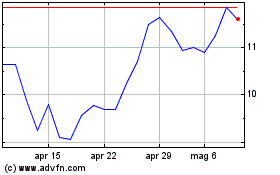

Grafico Azioni Hoffmann Green Cement Te... (EU:ALHGR)

Storico

Da Dic 2023 a Dic 2024