McPhy Energy: On the Road to Decarbonisation with Hydrogen: ArcelorMittal, VEO and McPhy to Build Pilot Electrolysis Plant in Eisenhüttenstadt

05 Aprile 2023 - 5:45PM

McPhy Energy: On the Road to Decarbonisation with Hydrogen:

ArcelorMittal, VEO and McPhy to Build Pilot Electrolysis Plant in

Eisenhüttenstadt

- Newly developed electrolysis demonstration plant with 2 MW

capacity to go into operation in 2024

- Hydrogen to be used directly in steel production and for

logistics processes on the site

- The Brandenburgish Technical University Cottbus-Senftenberg is

providing scientific support for the project to further develop the

technology

- The state of Brandenburg is funding the project cost with

approximately five million euros

Eisenhüttenstadt (Germany) and Grenoble

(France), April 5, 2023 - 5:45 pm CEST - The global steel

and mining group ArcelorMittal is moving forward

on the path to climate-neutral steel production at its

Eisenhüttenstadt site. Together with energy supplier Vulkan

Energiewirtschaft Oderbrücke (VEO) - a joint venture

between the city of Eisenhüttenstadt and ArcelorMittal

- and McPhy Energy, specialized

in low-carbon hydrogen production and distribution equipment

(electrolyzers and refueling stations), ArcelorMittal

Eisenhüttenstadt will build a pilot electrolysis plant and a

hydrogen filling station on the plant site.

The innovative demonstration project includes

the supply of two McLyzer electrolysers with an output of 1 MW

each. In addition, a long-term 5-year service contract was agreed

upon. The state of Brandenburg is funding the project with 5.1

million euros as part of the regional innovation cluster.

The electrolysers will produce hydrogen for

direct use in steel production. The hydrogen will first be used in

the cold rolling mill. The hydrogen filling station is used to

refuel forklifts or trucks with some of the hydrogen produced. The

oxygen also generated during electrolysis is to be reused on site

in production, for example in the hot rolling mill.

Smart operating modes to increase energy

efficiency

Another goal is to optimize the overall energy

efficiency of the production site by testing newly developed smart

operating modes in real-world applications. They should make it

possible to determine the best combination of software and hardware

to improve system performance - comparable to software improvement

in aircraft by implementing an intelligent strategy to control

aircraft functions. The Brandenburgish Technical University (BTU)

Cottbus-Senftenberg is providing scientific support for the project

and analyzing data from hydrogen use at the demonstration plant to

improve efficiency and support further development of

electrolysers.

Reiner Blaschek, CEO ArcelorMittal

Germany: "The demonstration plant will serve H2 use in

steel production as well as the logistical use of hydrogen-powered

vehicles around steel production. With this project, we want to

examine and show how further emission reductions are possible now,

before a complete change in technology and the use of further

hydrogen in the coming years will fully convert production to

climate neutrality."

Prof. Dr. Jörg Steinbach, Minister of

Economics of the State of Brandenburg: “The use of

hydrogen in steel production contributes significantly to the

urgently needed hydrogen infrastructure as a necessary building

block for maintaining the steel industry in Brandenburg and for the

energy transition. The project couples the energy, industry and

mobility sectors and helps to reduce CO2 emissions in steel

production and in the state of Brandenburg in the long term.”

Jean-Baptiste Lucas, Chief Executive

Officer of McPhy: "We are proud to participate in this

large-scale and innovative project alongside ArcelorMittal and the

State of Brandenburg. This is our first major contract in the

industrial sector, one of the most strategic and promising

applications for green hydrogen. The work will be carried out in

Germany, close to our site in Wildau. This is a milestone in our

European expansion strategy and a proof of the importance of our

pan-European industrial set-up.”

Prof. Dr. Lars Röntzsch, BTU

Cottbus: “Increasing energy efficiency through the use of

intelligent operating modes in electrolysis is a challenging topic

that we are very happy to work on scientifically in order to make

our contribution to ensuring that this important future technology

enables climate-neutral operation in such an energy-intensive

industry as the steel industry. Hydrogen will be of great

importance as a green energy carrier for industry and mobility in

Brandenburg.”

ABOUT ARCELORMITTAL

Germany

With a production volume of around 8 million

tonnes of crude steel, ArcelorMittal is one of the largest steel

manufacturers in Germany. The automotive, construction and

packaging industries are among its customers, as is the household

goods sector. The company operates four large production sites in

Germany. These include two integrated flat steel mills in Bremen

and Eisenhüttenstadt and two long steel mills in Hamburg and

Duisburg. In addition, the Group operates ArcelorMittal

Construction in Sandersdorf/Brehna, a production site with sales

for sandwich panels as well as profiling facilities for cassette,

trapezoidal, support, design and corrugated profiles. In addition,

the Group has a strong distribution network in Germany with four

steel service centres and ten steel trading locations.

ArcelorMittal operates a pipe mill in Altensteig. The group employs

about 8,500 people in Germany.

Further information is available at

https://germany.arcelormittal.com

Worldwide

ArcelorMittal is the world's leading steel and

mining company with a presence in 60 countries and primary

steelmaking facilities in 16 countries. In 2022, ArcelorMittal had

revenues of $79.8 billion and crude steel production of 59 million

tonnes, while iron ore production reached 45.3 million tonnes. Our

goal is to produce ever smarter steels that have positive benefits

for people and planet. Steels that are produced with innovative

processes that use less energy, emit significantly less carbon and

reduce costs. Steels that are cleaner, stronger and reusable.

Steels for electric vehicles and renewable energy infrastructure

that will support society as it moves through the new century. With

steel at our core, our inventive people and an entrepreneurial

culture at our heart, we will help the world make this

transformation. This is what it takes to be the steel company of

the future. ArcelorMittal is listed on the New York (MT), Amsterdam

(MT), Paris (MT), Luxembourg (MT) and Spanish stock exchanges of

Barcelona, Bilbao, Madrid and Valencia (MTS).

For more information on ArcelorMittal, please

visit http://corporate.arcelormittal.com

PRESS CONTACTS ARCELORMITTAL

|

BerlinArne LangnerT. +49 30

75445-556arne.langner@arcelormittal.com |

EisenhüttenstadtCarolin

Becker T. +49 3364

37-2010carolin.becker@arcelormittal.com |

ABOUT MCPHY

Specialized in hydrogen production and

distribution equipment, McPhy is contributing to the global

deployment of low-carbon hydrogen as a solution for energy

transition. With its complete range of products dedicated to the

industrial, mobility and energy sectors, McPhy offers its customers

turnkey solutions adapted to their applications in industrial raw

material supply, recharging of fuel cell electric vehicles or

storage and recovery of electricity surplus based on renewable

sources. As designer, manufacturer and integrator of hydrogen

equipment since 2008, McPhy has three development, engineering and

production centers in Europe (France, Italy, Germany). Its

international subsidiaries provide broad commercial coverage for

its innovative hydrogen solutions. McPhy is listed on Euronext

Paris (compartment B, ISIN code: FR0011742329, MCPHY).

CONTACTS MCPHY

|

NewCap |

|

|

Investor RelationsEmmanuel

HuynhT. +33 (0)1 44 71 94 99mcphy@newcap.eu |

Press relationsNicolas

MerigeauT. +33 (0)1 44 71 94 98mcphy@newcap.eu

|

Follow us on

@McPhyEnergy

- McPhy_PR ArcelorMittal VEO and McPhy

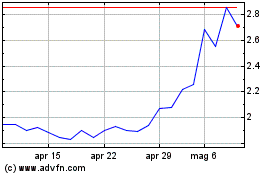

Grafico Azioni Mcphy Energy (EU:MCPHY)

Storico

Da Mar 2024 a Apr 2024

Grafico Azioni Mcphy Energy (EU:MCPHY)

Storico

Da Apr 2023 a Apr 2024